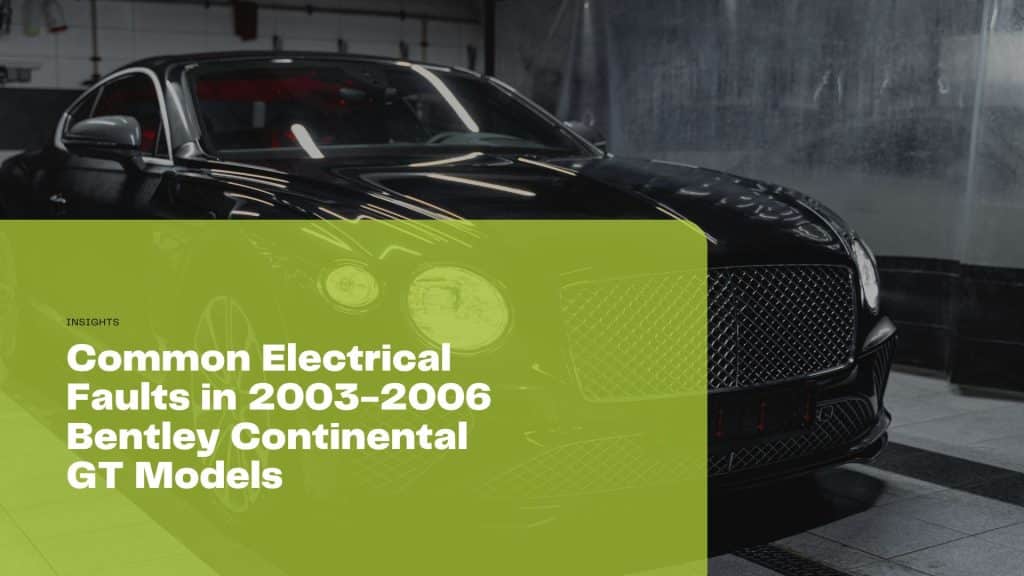

Introduction to Early Bentley Continental GT Electrical Systems

Overview of Electrical Architecture

The 2003-2006 Bentley Continental GT features a sophisticated electrical system, reflecting the brand’s emphasis on luxury, safety, and performance. The architecture relies on multiple control units managing engine, interior, exterior, and comfort functions. Its underlying network uses CAN bus technology, which ensures fast communication between modules while minimising wiring complexity. Key electrical nodes include the onboard control unit, body control modules, infotainment processors, and form a connected system that governs almost every aspect of the vehicle.

Importance in Luxury Vehicles

Understanding these electrical systems is vital for owners and technicians. Unlike simpler cars, a luxury vehicle’s value and comfort hinge on flawless electronic performance. Systems such as adaptive lighting, heated seating, electronic suspension, and precise climate control all depend on reliable circuitry. When one component misbehaves, it can quickly affect several others due to the tightly integrated network. Maintaining such a system requires close attention to detail and knowledge of each module’s role.

Impact of Electrical Faults

Electrical faults in early Continental GTs tend to be more than minor irritations. A failed relay or poor connection can prevent the car from starting or result in erratic performance in safety and comfort features. Malfunctions may trigger warning lights, disable systems, or drain batteries. Once faults arise, owners may face inconvenient immobilisation or expensive repairs. Reliability in these models is closely linked to the condition of their electrical systems, making proactive care essential.

Battery System Issues and Dual Battery Configuration

Overview of the Dual Battery System

The early Bentley Continental GT uses a dual battery arrangement, with two separate batteries performing different roles. One battery, often termed the ‘main systems battery’, powers a wide range of electronic modules and comfort features. The second, the ‘starter battery’, is dedicated to providing reliable current for engine cranking. This division is essential for maintaining stable voltage levels across a vehicle packed with electrical systems, helping to prevent non-start conditions and loss of vital functions after periods of inactivity.

Common Causes of Battery Drain

Battery drainage is a persistent issue seen in 2003-2006 Continental GT models. Electrical modules may continue to draw current when the vehicle is shutdown, leading to gradual battery depletion over several days. Common contributors to these parasitic drains include malfunctioning control units, boot lights that fail to turn off, or faulty switches. Unauthorised aftermarket accessories, such as non-original sound systems or tracking devices, can also introduce additional current draw if not installed correctly. In some cases, moisture ingress in wiring or modules promotes slow battery loss, especially if the vehicle is left unused for extended periods.

Impact of Proximity Key Systems

Proximity key systems introduce another layer of battery demand. These systems employ sensors that continuously scan for a signal from the vehicle’s key fob, even when the car is locked and stationary. This constant communication, while enhancing convenience and security, increases the baseline electrical load. If the fob is left within close range, the system may remain active longer than necessary, accelerating battery discharge. Owners may notice the need for more frequent battery charging or even recurring non-start issues.

Proper management of both batteries and awareness of factors leading to excessive drain are essential for reliable operation. Attention to battery health lays the groundwork for identifying further electrical problems which may arise in systems dependent on consistent voltage and current.

Starting System Failures

Common Starter Motor Issues

Early Bentley Continental GT models are equipped with robust starter motors, yet owners may experience intermittent or complete starting failures. Signs include repeated clicking noises, slow engine turnover, or no response when attempting to start. These issues often stem from internal wear—such as worn brushes or faulty solenoids—or poor electrical contact. The dual battery system means a weak starter battery can easily manifest as starter issues, so it’s important to check both battery condition and cable integrity.

Immobiliser System Faults

The immobiliser, designed for enhanced security, can sometimes prevent the engine from starting even if the battery and starter motor are functional. Faulty immobiliser control units, key synchronisation issues, or damaged antennas can result in a non-start situation. Symptoms include warning lights on the dashboard or “Key Not Recognised” messages. Occasionally, proximity key system miscommunication or external electromagnetic interference may block the authorisation signal required for ignition. Regular re-synchronisation of keys and system checks help reduce such disruptions.

433 Relay Troubleshooting

Early Continental GTs utilise a 433 relay for critical engine and ignition functions. Relay failure is a notable weak point, particularly as vehicles age. Symptoms of a failing 433 relay include random starting failures, intermittent ignition response, or even stalling after starting. Diagnosing the relay involves locating it in the fuse and relay box, checking for signs of overheating, and testing for continuity. Replacement is straightforward, but using high-quality parts is essential to prevent recurring issues.

Addressing starter and immobiliser faults promptly supports overall reliability and minimises knock-on electrical issues. Regular checks and targeted diagnostics help ensure smooth operation for years to come.

Charging System Complications

Alternator Failures and Symptoms

Early Bentley Continental GT models from 2003 to 2006 commonly experience alternator failures. The alternator is responsible for charging the battery and powering multiple electronic systems when the engine runs. Failure of this unit may lead to a range of issues, including the battery warning light illuminating on the dashboard, dimming or flickering headlights, and electronic accessories malfunctioning. Owners may also face slow window or seat operation, a dead battery, or a persistent burning rubber smell, signalling belt or alternator wear. In some cases, strange growling or whining sounds under the bonnet point to bearing or belt problems.

Wiring and Connection Issues

Beyond alternator wear, wiring and connector faults can compromise the charging system. Frayed, dirty, or corroded cables between the alternator and battery interrupt proper current flow. These conditions may cause battery undercharging or erratic voltage delivery to essential systems. Loose or dirty alternator mounts further reduce efficiency and can be a hidden culprit in persistent charging faults.

Diagnostic Approaches

Diagnosing charging system issues in a Continental GT involves more than swapping the alternator. A multimeter test on the battery, while the engine runs, should show between 14.2 to 14.7 volts for a healthy system. Any reading outside this range could indicate alternator or rectifier problems. Inspect wiring for wear, check all related fuses and relays, and listen for abnormal noises during operation. Addressing alternator and wiring issues early helps maintain electrical reliability and reduces the likelihood of sudden failures.

Electrical Component Malfunctions

Infotainment and Electronic Control Unit Failures

Early Bentley Continental GT models often experience problems in their infotainment and electronic control units. The infotainment system may freeze on the Bentley logo, become unresponsive, or repeatedly reboot. Such issues can disrupt navigation, audio, Bluetooth connectivity, and even rear camera operation. While a reset function exists, persistent faults may require specialised diagnostics or component replacement.

Faults within the electronic control unit (ECU) can present as sudden stalling, difficulty starting, or fluctuating acceleration. This stems from the ECU’s inability to read or interpret sensor data correctly. The result can be poor fuel delivery, ignition inconsistencies, and, ultimately, reduced engine performance. Such symptoms require prompt attention, as faulty ECUs can significantly impact safety and drivability.

Window Motors and Power Accessories

Power window failure is frequently reported in these vehicles. Symptoms include slow window operation, windows stuck in the open or closed position, or complete loss of function. Faulty window motors or defective switches are common causes, and may also impact other accessories like door locks. Malfunctioning power accessories are disruptive but usually straightforward to diagnose and repair with the right expertise.

Interior and Exterior Lighting Faults

Bentley owners may also face lighting system faults. Problems affect both interior and exterior lights, including headlights, taillights, and cabin illumination. You might notice lights that flicker, dim, or fail entirely. Causes often include blown bulbs, faulty wiring, or control module defects. These issues are not just cosmetic—lighting faults reduce visibility and can compromise safety if left unaddressed.

Climate Control System Electrical Faults

Air Conditioning Electrical Failures

A common issue in early Bentley Continental GT models is electrical faults within the air conditioning system. Owners may notice the system fails to cool, the fan operates intermittently, or there is a complete lack of response from the climate controls. These symptoms often relate to faulty blower motor control modules, damaged sensors, or intermittent loss of power to the AC controller. Control unit errors can also cause the system to default to an inoperative state until reset. Ensuring the main electrical supply to the air conditioning system is stable and free from corrosion is vital for sustained performance.

Heating System Electrical Issues

Electrical complications affecting the heating system include malfunctioning seat heaters, erratic temperature adjustment, and non-operational heater fans. These problems typically originate from failed heater control units, worn wiring, or faulty control buttons. In some cases, sensors that monitor cabin or coolant temperature may send incorrect signals, resulting in inadequate heating or failure to activate. Investigating connections and replacing defective modules helps restore reliable heating functionality.

Air Suspension System Electrical Complications

The air suspension system in early Continental GTs is electronically controlled and sensitive to voltage irregularities or poor connections. Electrical faults may manifest as warning lights, an uneven ride height, or the inability to adjust suspension settings. Common causes include corroded connectors, disrupted wiring near the wheel arches, or failed air suspension control modules. Regular inspection and prompt replacement of faulty connections are crucial to prevent more serious suspension failures.

Wiring and Connector Problems

Ageing and Deterioration of Wiring Harnesses

As early Bentley Continental GT models age, their wiring harnesses are exposed to heat, mechanical stress, and fluctuating humidity. Over time, the insulation on wires can become brittle. Cracking or hardening often leads to exposed conductors, increasing the risk of short circuits. Where wiring is routed through door sills or engine bays, movement and vibration can cause insulation wear. This gradual degradation is a common cause of unexplained electrical issues and intermittent faults.

Corrosion Issues in Connectors

Corrosion of electrical connectors is a recurring problem in Continental GTs, especially in the UK climate. Moisture ingress, whether from driving conditions or minor flooding, can lead to oxidised terminals, greenish deposits, and reduced conductivity. This is frequently seen in door connectors, boot compartments, and underbody harness junctions. Once corroded, connectors can cause anything from non-functioning accessories to full module failures. Rust and corrosion are not just a cosmetic concern—they can affect sensing circuits and high current paths required for engine or climate systems operation.

Ground Connection Faults and Systemic Effects

Poor or corroded ground connections are a leading cause of electrical gremlins in older luxury vehicles. Signs of ground faults include flickering lights, erratic electronic behaviour, and even engine starting problems. The Bentley Continental GT has multiple ground points, and a failure at any one can cause widespread faults. Ensuring that ground straps are intact and ground bolts remain clean is critical to maintaining system reliability. Checking grounds is a simple yet essential first step in electrical diagnosis.

Fuse and Relay Failures

Critical Fuse Points and Common Failures

The 2003-2006 Bentley Continental GT relies on a network of fuses to protect essential circuits. Critical fuse points are spread throughout the vehicle, often grouped in main fuse panels located under the bonnet, within the dashboard, and in the boot. A blown fuse can result in the sudden loss of power to systems such as lighting, infotainment, or even power steering. Common failures include fuses degrading due to age or drawing too much current, which leads to intermittent or total system loss.

Checking fuses is a fundamental troubleshooting step when electrical functions fail, and blown fuses are often the root cause of non-operational features like power seats or window switches. Owners searching for fuse diagrams should reference Bentley-specific service documentation or community forums, as detailed locations can vary between model years.

Relay Problems Affecting Multiple Systems

Relays in the Continental GT act as electrically operated switches, allowing low-current circuits to control high-current consumers. When relays fail, affected systems can range from the starter and fuel pump to the climate control fan. Relay contacts may wear or develop internal corrosion, causing intermittent faults. Additionally, relay-related issues often result in cascading failures—one faulty relay might stop both the starter and auxiliary fans, for example. Replacing a defective relay is generally straightforward once the faulty unit is identified, but gaining access sometimes requires careful disassembly.

Locating and Diagnosing Electrical Control Modules

Electrical control modules, responsible for managing subsystems such as doors, seats, and the immobiliser, are typically found beneath seats, within the dashboard, or behind trim panels. Diagnosing issues with these modules often requires specialised diagnostic tools and careful voltage measurements. Faulty modules may trigger multiple errors across the vehicle’s systems, making accurate diagnosis and replacement key to restoring full functionality. Ensuring firm connections and corrosion-free contacts is crucial for sustained reliability.

This systematic approach to addressing fuse and relay failures is important in isolating underlying faults and restoring proper electrical operation. Regular inspection helps maintain system integrity and extends the lifespan of critical components.

Diagnostic Approaches for Continental GT Electrical Issues

Professional Diagnostic Tools and Techniques

Accurate diagnosis of the Bentley Continental GT’s electrical faults requires specialised equipment. Dedicated Bentley diagnostic tools, often available through authorised repairers and suppliers, interface directly with electronic control modules. These tools allow technicians to read manufacturer-specific fault codes, monitor real-time sensor data, and initiate system tests. Using manufacturer-approved diagnostic hardware and software ensures full visibility into the car’s electrical systems, helping to pinpoint issues ranging from faulty sensors to complex network faults. This process is vital for maintaining safety and performance standards in these luxury vehicles.

DIY Troubleshooting Methods

While professional tools provide comprehensive fault analysis, owners may carry out simple checks for basic faults. Using a standard OBD2 scanner can help identify generic engine and transmission error codes. Inspecting fuses and relays for visual damage, testing battery voltage with a multimeter, and examining connectors for signs of corrosion are effective first steps. If issues persist after these checks, it is recommended to seek professional assistance to prevent further damage.

Interpreting Error Codes and Warning Lights

Modern Bentleys are equipped with an advanced warning light system. Dash symbols indicate everything from minor bulb failures to serious system faults such as charging failures or air suspension issues. When a warning light appears, consulting the owner’s manual helps interpret its meaning. For persistent or critical warnings, connecting a diagnostic tool will retrieve specific codes, revealing the underlying problem. Quick attention to these warnings allows early intervention, reducing the risk of major faults.

Preventative Maintenance and Solutions

Regular Electrical System Maintenance

Routine care is key to the long-term health of a Bentley Continental GT’s electrical systems. Owners should follow a strict maintenance schedule, including regular checks on battery condition, fuse health, and wiring integrity. Inspecting for corrosion, particularly at connectors and grounds, helps prevent many common faults before they escalate. Keeping the vehicle’s software updated also aids in minimising glitches in control units. When unusual electrical symptoms appear, seek professional diagnostics promptly to avoid potential cascade failures.

The Value of OEM Parts

Opting for original equipment manufacturer (OEM) parts during electrical repairs is essential. OEM components are designed specifically for the Continental GT, ensuring reliable compatibility and performance. They are manufactured to Bentley’s standards for durability, undergo rigorous testing, and provide optimal fit. In contrast, aftermarket alternatives may lack the same level of quality, leading to potential issues with safety and longevity. Using OEM parts can reduce the likelihood of repeat faults and unplanned downtime, offering peace of mind with every repair.

Long-Term Strategies for Reliability

A Bentley’s electrical reliability benefits from proactive steps such as scheduled battery replacements and comprehensive system inspections every few years. Owners should address warning lights without delay and avoid unauthorised modifications, as these can introduce parasitic drains or compatibility problems. Engaging certified Bentley specialists for repairs and scheduled servicing ensures that potential issues are addressed with the expertise these complex vehicles require.

Proper preventative measures and the use of correct parts are central to electrical system longevity. This approach not only maintains performance but also preserves the luxury experience the Continental GT is renowned for.

Conclusion: Preserving Your Continental GT’s Electrical Integrity

Reflecting on Key Vulnerabilities

Early Bentley Continental GT models from 2003 to 2006 possess a sophisticated yet sensitive electrical system. Over time, owners often encounter issues with dual battery configurations, starter motor failures, and unpredictable alternator behaviour. Infotainment glitches, problems with electronic control units, and erratic climate control further contribute to frequent owner concerns. Wiring deterioration, corroded connectors, and ground faults are also prevalent, leading to inconsistent performance or unexplained failures. Regular fuse and relay checks form another weak point, as these components become more failure-prone with age and use.

Importance of Specialised Expertise

Addressing these failures goes beyond general automotive knowledge. Routine checks on battery health, fuse boxes, and wiring are vital, but the complexity of Bentley’s systems demands a level of technical understanding unique to the marque. Specialised Bentley technicians use diagnostic equipment designed for these vehicles, ensuring precise fault identification and correct rectification. The use of Original Equipment Manufacturer (OEM) parts is critical to maintain proper function, as non-genuine parts can introduce compatibility problems or accelerate wear.

Ensuring Long-Lasting Reliability

Regular, professional maintenance preserves not only the driving experience but also the long-term value of these luxury vehicles. Timely servicing addresses minor faults before escalation, reducing long-term running costs and unexpected breakdowns. Taking a proactive approach by adhering to Bentley’s service schedules, attending to warning lights promptly, and relying on experienced technicians forms the foundation of electrical system integrity.

Transitioning beyond the technical, a well-preserved electrical system enables your Bentley Continental GT to deliver its renowned comfort, safety, and performance for years to come.