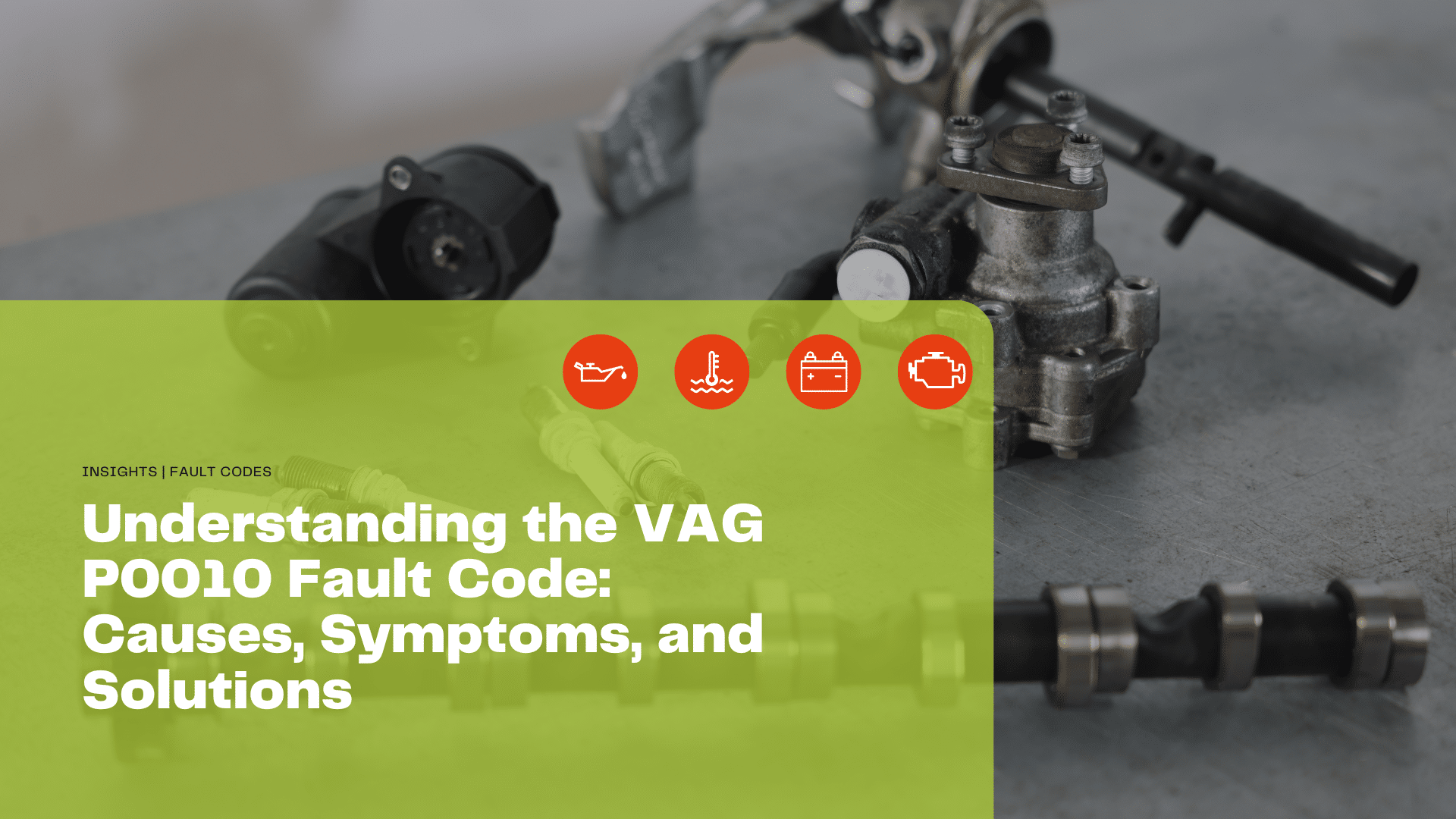

Introduction

The VAG P0010 fault code is a critical diagnostic trouble code (DTC) associated with the camshaft position actuator in vehicles from the Volkswagen Audi Group (VAG). This code signals a malfunction in the variable valve timing (VVT) system, which is essential for optimising engine performance and efficiency. The camshaft position actuator is key in allowing the engine to adjust valve timing according to operating conditions. When the P0010 fault code triggers, it can lead to engine performance issues, including reduced power output, increased fuel consumption, and overall inefficient operation.

Addressing the implications of the P0010 fault code is crucial for vehicle owners and automotive technicians. Timely diagnosis and repair not only enhance vehicle performance but also prevent potential long-term damage to the engine. In this article, we will explore the details of the VAG P0010 fault code, including its causes, symptoms, diagnostic processes, and recommended solutions.

Understanding the VAG P0010 Fault Code: An Overview

The P0010 fault code specifically relates to the performance of the camshaft position actuator in VAG vehicles, which include brands such as Volkswagen, Audi, Skoda, and SEAT. This code indicates that the engine control module (ECM) has detected an issue with the camshaft position actuator’s performance, vital for adjusting the timing of the intake and exhaust valves. The actuator alters the camshaft position, enabling or disabling the VVT functionality.

In the UK, the P0010 fault code is commonly associated with specific engine codes, including:

- 1.8TSI and 2.0TSI engines (e.g., EA888 Gen 1, 2, and 3)

- 1.6 TDI and 2.0 TDI engines (e.g., common rail diesels)

The Role of the Camshaft Position Actuator

The camshaft position actuator controls the camshaft’s position relative to the crankshaft. By adjusting the timing of valve openings and closings, the actuator allows for optimal engine performance across various RPM ranges. Under different loads and speeds, the actuator modifies the camshaft position to enhance efficiency and power delivery, especially during acceleration, which improves airflow into the engine.

Relationship Between P0010 Code and Engine Performance

When the P0010 fault code appears, it signifies a malfunction in the camshaft position actuator, leading to several cascading effects on engine performance. Symptoms such as decreased power, rough idling, and increased fuel consumption may emerge. Understanding the link between the P0010 code and engine performance is vital for technicians diagnosing the issue and owners seeking to maintain their vehicle’s functionality.

Common Causes of the P0010 Fault Code

Several factors can trigger the P0010 fault code, and understanding these causes is crucial for effective troubleshooting and repair.

Faulty Camshaft Position Actuator

A malfunctioning camshaft position actuator is one of the most common reasons for the P0010 fault code. This component can fail due to wear and tear, exposure to contaminants, or electrical faults. When the actuator fails, it may not adjust the camshaft position correctly, leading to performance issues and triggering the fault code.

Wiring or Connector Issues

Faulty wiring or poor connections between the actuator and the ECM can also cause the P0010 code to appear. Damaged wiring, corroded connectors, or loose connections can disrupt the signal transmission necessary for the actuator’s operation. A thorough inspection of the wiring harness and connectors is essential for diagnosing this issue.

Oil-Related Problems

The VVT system relies on proper oil flow and pressure to function effectively. Low oil levels, dirty or degraded oil, or a clogged oil filter can inhibit the actuator’s performance. If the oil supply to the VVT system is compromised, it can trigger the P0010 fault code. Regular oil changes and maintenance are vital to prevent such oil-related issues.

Worn Timing Components

The timing chain or belt can also influence the P0010 fault code. If these components are worn or damaged, they may not maintain the required synchronization between the crankshaft and camshaft. This can lead to timing discrepancies, prompting the ECM to trigger the fault code.

Malfunctioning Sensors

The camshaft position sensor and crankshaft position sensor play significant roles in the VVT system’s operation. If either sensor is faulty, it can lead to incorrect readings sent to the ECM, resulting in the P0010 code. Diagnosing sensor issues often requires advanced diagnostic tools for accurate identification.

Symptoms Indicating the P0010 Fault Code

Vehicle owners may notice several symptoms when the P0010 fault code is present. Recognising these signs is essential for prompt diagnosis and repair.

Check Engine Light Activation

One of the most apparent indicators of the P0010 fault code is the illumination of the “Check Engine” light on the dashboard. This warning signifies that the vehicle’s onboard diagnostics system has detected an issue, prompting further investigation. While the check engine light can signal various problems, its presence alongside specific symptoms related to engine performance should alert owners to the possibility of the P0010 code.

Rough or Unstable Idle

Drivers may experience rough or unstable idling when the P0010 fault code is triggered. This symptom occurs as the engine struggles to maintain a consistent idle speed due to improper valve timing. An unstable idle can be particularly concerning, as it indicates that the engine may not be operating efficiently.

Poor Engine Performance

A common manifestation of the P0010 fault code is a noticeable decline in engine performance. Drivers may find that their vehicles lack power during acceleration, struggle to maintain speed, or experience hesitation when pressing the accelerator. These performance issues can significantly impact the overall driving experience and may necessitate immediate attention.

Increased Fuel Consumption

Another symptom associated with the P0010 fault code is increased fuel consumption. When the VVT system is not functioning correctly, the engine may operate less efficiently, leading to higher fuel usage. Vehicle owners may notice that they are refuelling more frequently, which can be both inconvenient and costly.

Unusual Engine Noises

In some cases, the presence of the P0010 fault code may result in unusual engine noises. These sounds can manifest as knocking, ticking, or other irregular sounds that indicate a problem with the engine’s timing or valve operation. Such noises should not be ignored, as they can signify underlying issues that may require immediate attention.

Diagnosing the P0010 Fault Code

Diagnosing the P0010 fault code requires a systematic approach to identify the root cause of the issue. Automotive technicians typically follow a series of steps to confirm the fault code and rule out other potential problems.

Using Diagnostic Tools

The first step in diagnosing the P0010 fault code is using an OBD-II scanner to retrieve the fault codes from the vehicle’s onboard diagnostics system. This tool provides valuable information about the specific codes present and can help technicians identify the nature of the problem. The P0010 code typically translates to:

- “Camshaft Position Actuator A – Circuit Malfunction (Bank 1)”

- “Camshaft Position Actuator A – Circuit Range/Performance (Bank 1)”

Once the P0010 code is confirmed, technicians may also look for related codes that could provide additional context.

Visual Inspections

A thorough visual inspection of the relevant components is essential in the diagnostic process. Technicians will examine the camshaft position actuator, wiring, connectors, and timing components for signs of wear, damage, or corrosion. Any visible issues should be addressed before proceeding with further diagnostics.

Testing the Camshaft Position Actuator

If the actuator is suspected to be faulty, technicians will perform tests to confirm its functionality. This may involve checking the actuator’s resistance and ensuring that it responds correctly to signals from the ECM. If the actuator fails these tests, it may need to be replaced.

Evaluating Oil Quality and Levels

Given the importance of oil flow to the VVT system, technicians will also assess the engine oil quality and levels. Low or contaminated oil can severely impact the actuator’s performance. If necessary, an oil change or filter replacement may be recommended to restore optimal function.

Verifying Sensor Functionality

As part of the diagnostic process, technicians will evaluate the performance of the camshaft and crankshaft position sensors. This may involve testing their resistance and ensuring they provide accurate readings to the ECM. If either sensor is found to be faulty, replacement may be necessary to resolve the P0010 fault code.

Solutions and Repairs for the P0010 Fault Code

Addressing the P0010 fault code involves inspecting, repairing, and replacing faulty components. Understanding the appropriate steps to take is essential for restoring engine performance.

Checking Engine Oil Levels and Quality

The first step in resolving the P0010 fault code is to assess the engine oil levels and quality. Technicians should ensure that the oil is at the recommended level and that it is clean and free from contaminants. If the oil is dirty or degraded, an oil change should be performed to restore optimal flow to the VVT system.

Inspecting Wiring and Connectors

If wiring or connector issues are suspected, technicians must conduct a thorough examination of the wiring harness leading to the camshaft position actuator. Repairs may involve re-establishing connections, replacing damaged wires, or cleaning corroded connectors to ensure proper electrical flow.

Testing and Replacing the Actuator

If the camshaft position actuator is confirmed to be faulty, it will need to be replaced. Technicians should source a high-quality replacement component that meets OEM specifications to ensure compatibility and performance. The replacement process typically involves disconnecting the battery, removing the faulty actuator, and installing the new unit while ensuring all connections are secure. After replacement, it may be necessary to perform a “basic setting” or “adaptation” procedure using a diagnostic tool to ensure that the ECM properly recognizes and controls the new actuator.

Examining Timing Components

In cases where worn timing components are identified, technicians must assess whether the timing chain or belt requires replacement. This process may involve disassembling parts of the engine to access the timing components and ensure that they are correctly synchronised. Proper installation and alignment are crucial to prevent the recurrence of the P0010 fault code.

Addressing Sensor Issues

Should sensor faults be detected during diagnosis, replacing the faulty camshaft or crankshaft position sensor is necessary. As with the actuator, sourcing quality replacement sensors is critical for maintaining engine performance. Following replacement, technicians should clear the fault codes and conduct a test drive to ensure that the P0010 code does not reappear.

Conclusion

The VAG P0010 fault code is a significant indicator of potential issues within the camshaft position actuator and the variable valve timing system in VAG vehicles. Understanding its causes, symptoms, and diagnostic processes is essential for both vehicle owners and automotive technicians. Prompt diagnosis and repair can mitigate engine performance issues and prevent further complications down the line.

Effective management of the VAG P0010 fault code not only enhances the driving experience but also ensures the longevity and reliability of the vehicle. Regular maintenance, including monitoring oil quality and levels, inspecting wiring and connectors, and addressing actuator and sensor functionality, is vital for optimal engine performance. By staying vigilant and proactive, vehicle owners can ensure their engines operate efficiently and effectively, preventing the onset of more severe issues associated with the P0010 fault code.